Upgrading shift linkage

Moderators: GRNSHRK, ron, bfons

Upgrading shift linkage

Currently running my '87 635csi with some rough shift linkage issues. The PO converted the car from auto and installed a Metric Mechanic transmission and clutch assy. Sine the linkage has been jamming up on me and I can see a lot of slop when I'm under the car I have some serious upgrade questions.

The shifter has the sheet metal console and I wondering if I can upgrade to the aluminum shift console or do I end up rebuilding the sheet metal one. I want to upgrade all the linkage, maybe spring for the UCC package, and I am wondering what else I should do while I have it torn apart?

Since I'm not sure what parts were used in the swap, is it safe to just order all the parts for the sheet metal console assuming I can't change it out? I'd rather order more parts than be short as I will tying up my mechanics lift.

Thanks Guys,

Tom in Reno, NV

The shifter has the sheet metal console and I wondering if I can upgrade to the aluminum shift console or do I end up rebuilding the sheet metal one. I want to upgrade all the linkage, maybe spring for the UCC package, and I am wondering what else I should do while I have it torn apart?

Since I'm not sure what parts were used in the swap, is it safe to just order all the parts for the sheet metal console assuming I can't change it out? I'd rather order more parts than be short as I will tying up my mechanics lift.

Thanks Guys,

Tom in Reno, NV

Tom in Reno, NV

'87 635csi

'07 328i

'87 635csi

'07 328i

Re: Upgrading shift linkage

the sheet metal console mounts differently onto the back of the gearbox, and not many gearboxes have dual mountings, so you may not have any choice about which type of console you use. There are subtle differences in the other parts too. The linkage parts that wear are mostly similar, so in terms of wear, there is no great advantage in one type over the other.

Differences are

1) that the 'knuckle' that goes onto the back of the gearbox has a wider bushing in the later versions (which also have aluminium consoles)

2) the main swivel for the gearstick is in two halves with the steel console, but is a snap-in affair with the aluminium console.

3) the sheet metal console bolts onto the gearbox via two blocks that are drilled at right angles. These often work loose, or even break.

4) if the gearbox mountings go bad, the sheet metal console will put undue stress on the back of the gearbox if it is pushed sideways

I have upgraded the sheet metal console by

1) rebuilding all the bushings

2) fitting a single-turn spring to preload the knuckle joint (instead of using a foam buffer that falls apart when it gets saturated with oil)

3) fitting a short-throw gear lever

4) fitting a stronger spring that preloads the upper half of the main ball joint housing

cheers

Differences are

1) that the 'knuckle' that goes onto the back of the gearbox has a wider bushing in the later versions (which also have aluminium consoles)

2) the main swivel for the gearstick is in two halves with the steel console, but is a snap-in affair with the aluminium console.

3) the sheet metal console bolts onto the gearbox via two blocks that are drilled at right angles. These often work loose, or even break.

4) if the gearbox mountings go bad, the sheet metal console will put undue stress on the back of the gearbox if it is pushed sideways

I have upgraded the sheet metal console by

1) rebuilding all the bushings

2) fitting a single-turn spring to preload the knuckle joint (instead of using a foam buffer that falls apart when it gets saturated with oil)

3) fitting a short-throw gear lever

4) fitting a stronger spring that preloads the upper half of the main ball joint housing

cheers

~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Re: Upgrading shift linkage

I have the sheet metal console on mine as well. Is a 265/6 trans. I'm wanting to upgrade to the aluminum on mine. What I've heard is that the 265 was used on the E30 M3 and there's a bracket that fits to where the sheet metal console mounts. The bracket fits to those mounts at the rear of the trans and that bracket allows you to use the aluminum piece. I've only heard of this upgrade and cannot say with confidence that this is indeed the fix.

Past:

84-318i, 85-318i, 85-635 CSi, 86-635 CSi

Current:

87-635 CSi

84-318i, 85-318i, 85-635 CSi, 86-635 CSi

Current:

87-635 CSi

-

wattsmonkey

- Platinum Member

- Posts: 1659

- Joined: Mon Jul 16, 2007 2:58 pm

- Location: Cheltenham, U.K.

Re: Upgrading shift linkage

To echo Brucey's comments, I'm not sure that the aluminium shift bracket is an upgrade over the sheet metal one, but it is different!

In addition to Brucey's upgrades, you'll probably find that the rubber mount at the very rear of the sheet metal console is as floppy as you like. An off-the-shelf universal exhaust mount "bobbin" is a well-documented fix for this.

In addition to Brucey's upgrades, you'll probably find that the rubber mount at the very rear of the sheet metal console is as floppy as you like. An off-the-shelf universal exhaust mount "bobbin" is a well-documented fix for this.

"Most of it necessary; all of it enjoyable." LJKS

'84 635CSi, dogleg...itbs and supercharger????? Eaton Mess

'84 635CSi, dogleg...itbs and supercharger????? Eaton Mess

-

brickwhite

- Posts: 797

- Joined: Wed Sep 01, 2010 3:29 pm

- Location: Broomfield, CO

Re: Upgrading shift linkage

here is a write up on how to convert a 265 to a aluminum shift mount...

http://www.mye28.com/viewtopic.php?t=59684

https://www.r3vlimited.com/board/showth ... p?t=309740

But I would just update your steel mounts it's pretty easy and helps alot.

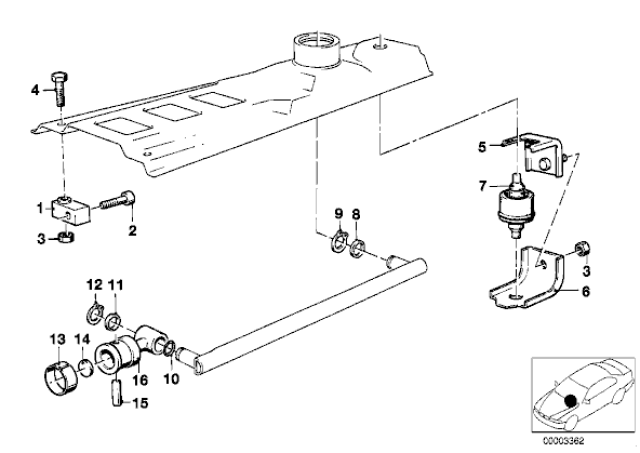

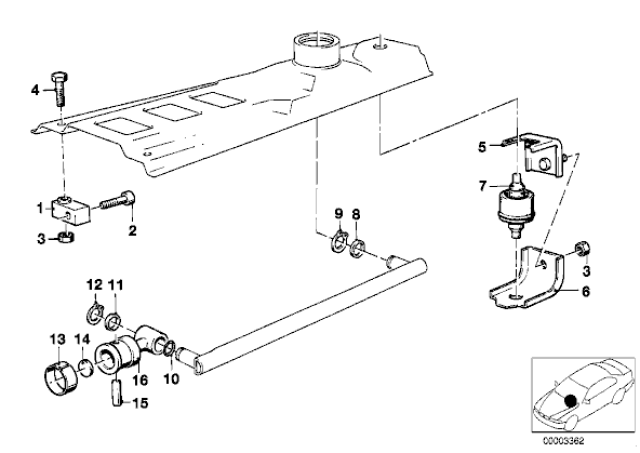

you can replace the rear mount #7 with a piece of rubber and a large bolt. and update the #1

My guess if you have that much slop... #7 is not even attached anymore.

http://www.mye28.com/viewtopic.php?t=59684

https://www.r3vlimited.com/board/showth ... p?t=309740

But I would just update your steel mounts it's pretty easy and helps alot.

you can replace the rear mount #7 with a piece of rubber and a large bolt. and update the #1

My guess if you have that much slop... #7 is not even attached anymore.

- 12 535i

- 92 325ic

- 92 325ic

Re: Upgrading shift linkage

i made some soild mounts ( #1 above) that i thought helped a lot. your welcome to them if you want to cover shipping.

.1977 H&B 630CSI - http://www.sidedraftsix.com.

- Tim Bradham

- Posts: 47

- Joined: Thu Aug 29, 2013 12:51 pm

- Location: Fayetteville, N.c.

- Contact:

Re: Upgrading shift linkage

What’s a good short throw you’d recommend? Thanks TimBrucey wrote: ↑Mon Sep 18, 2017 3:41 pm the sheet metal console mounts differently onto the back of the gearbox, and not many gearboxes have dual mountings, so you may not have any choice about which type of console you use. There are subtle differences in the other parts too. The linkage parts that wear are mostly similar, so in terms of wear, there is no great advantage in one type over the other.

Differences are

1) that the 'knuckle' that goes onto the back of the gearbox has a wider bushing in the later versions (which also have aluminium consoles)

2) the main swivel for the gearstick is in two halves with the steel console, but is a snap-in affair with the aluminium console.

3) the sheet metal console bolts onto the gearbox via two blocks that are drilled at right angles. These often work loose, or even break.

4) if the gearbox mountings go bad, the sheet metal console will put undue stress on the back of the gearbox if it is pushed sideways

I have upgraded the sheet metal console by

1) rebuilding all the bushings

2) fitting a single-turn spring to preload the knuckle joint (instead of using a foam buffer that falls apart when it gets saturated with oil)

3) fitting a short-throw gear lever

4) fitting a stronger spring that preloads the upper half of the main ball joint housing

cheers

"Bradham's Design"

-

brickwhite

- Posts: 797

- Joined: Wed Sep 01, 2010 3:29 pm

- Location: Broomfield, CO

-

bpoliakoff

- Platinum Member

- Posts: 3320

- Joined: Thu Sep 28, 2006 9:28 pm

- Location: scottsdale, arizona

- Contact:

Re: Upgrading shift linkage

Z3, 4 different lengths to chose from. I used my original and welded a 5/8" spacer between thee "ball" and the end `of the stick. My shifts are easy and click right in. $20 was better than $75 plus. You can add a larger spacer, but to what end? The shorter the throw, the more energy it will require to shift.

81 Euro 635 M90 with motronic. Currently under a complete nut and bolt restoration. Pictures at

flickr.com/photos/bertsphotos.

flickr.com/photos/bertsphotos.